Your pickup truck does a lot more than get you from Point A to Point B. Whether it’s your gateway to the great outdoors or your means to a job well done, even the highest performing vehicles need a little TLC.

Proper upkeep is essential for keeping your truck efficient and reliable, and allows you to address potential issues before they escalate into larger, pricier problems. This not only extends the lifespan of your truck but can also reduce long-term operating costs. In fact, one industry report found that preventative vehicle maintenance is associated with 40% lower repair costs compared to reactive approaches.1

In this guide, we go over everything you need to know about annual truck maintenance, including a comprehensive checklist to help keep your vehicle in top condition.

Annual Truck Maintenance Checklist:

1. Check Your Fluids and Filters

Your truck needs fluids like engine oil, coolant, and brake fluid to keep critical systems lubricated and prevent them from overheating. It also has vent filters to clean the air that enters the cabin. Both require regular checks and changes to keep your truck functioning effectively and safely.

It’s a good idea to check and top off all fluids and replace your filters at least once a year, or sooner, depending on how much you use your truck. This includes:

- Power Steering Fluid: hydraulic fluid that supports smooth steering

- Transmission Fluid: lubricates and cools your transmission’s moving parts while enabling smooth gear shifts

- Differential Fluid: lubricates the gears in your differential, which transfers power from the transmission to the wheels

- Windshield Washer Fluid: cleans dirt, bugs, and debris from the windshield for better visibility

- Cabin Air Filter: filters dust, pollen, and pollutants from outside air before it enters your truck’s interior

Below, we cover maintenance schedules for some of the most critical fluids in more detail.

Engine Oil and Filter

Engine oil helps lubricate, reduce friction, and dissipate heat to prevent damage. The engine also needs an oil filter to remove contaminants from the oil, keeping it clean and effective.

Check your oil level monthly and change both the oil and filter per the truck manufacturer’s recommendations, which is typically every 5,000–7,500 miles.

Engine Coolant (Antifreeze)

Coolant, also called antifreeze, is a fluid that circulates through the engine and radiator to regulate the temperature. It’s essential for preventing both overheating and freezing.

Check your truck coolant levels every 3–6 months and only top off if it falls beneath the minimum line. A full coolant flush and replacement is generally recommended every 30,000 miles, or 1–2 years, but always check your owner’s manual first.

Brake Fluid

Brake fluid is a hydraulic liquid that helps transfer force from your brake pedal to the brake components. Without it, you wouldn’t be able to stop your truck safely. It also prevents corrosion and overheating.

Check your truck’s brake fluid level and condition every few months during routine maintenance. Replace it per the manufacturer’s recommendations, which is usually every 2–3 years, or 30,000–45,000 miles.

2. Check Your Hardware

Over time, your truck can experience normal wear from daily use, weather, and road conditions. At least once a year, it’s good to inspect the body of your truck, as well as all the safety hardware like windshield wipers and seatbelts, to make sure everything is still in good shape.

A good hardware safety check will include things like:

- Testing and replacing windshield wipers

- Checking that all your mirrors are accounted for

- Looking for cracks or chips in the windshield

- Testing the horn

- Making sure all seatbelts function

Below are some of the most important exterior hardware components to check during your annual truck maintenance routine:

Tires and Suspension

A functioning tire and suspension system is vital for keeping your truck safe, efficient, and easy to handle. A tire and suspension inspection usually involves checking alignment, tire pressure, shock absorbers, and other key components. You may also want to have your tires rotated to improve traction and extend their lifespan.

Brakes

Brake inspections are essential to ensure safe handling, especially if you regularly haul heavy loads like trailers, boats, or other vehicles. A professional can thoroughly check your truck’s brake pads, drums, rotors, and lines to verify that everything is working properly.

Check your owner’s manual, but it’s generally recommended to have truck brakes inspected annually or every 20,000–60,000 miles, whichever comes sooner.

Ignition System

The ignition system is like your truck’s heartbeat; it can’t operate without it. That’s why it’s so important to have it evaluated at least once a year to ensure everything is operating safely and efficiently.

An ignition system evaluation typically involves checking the spark plugs, ignition coils, and battery connections for wear and function. While diesel-powered pickup trucks do not use spark plugs, gas-powered vehicles do, and they typically require replacement every 30,000 miles. Check your owner’s manual if you are unsure.

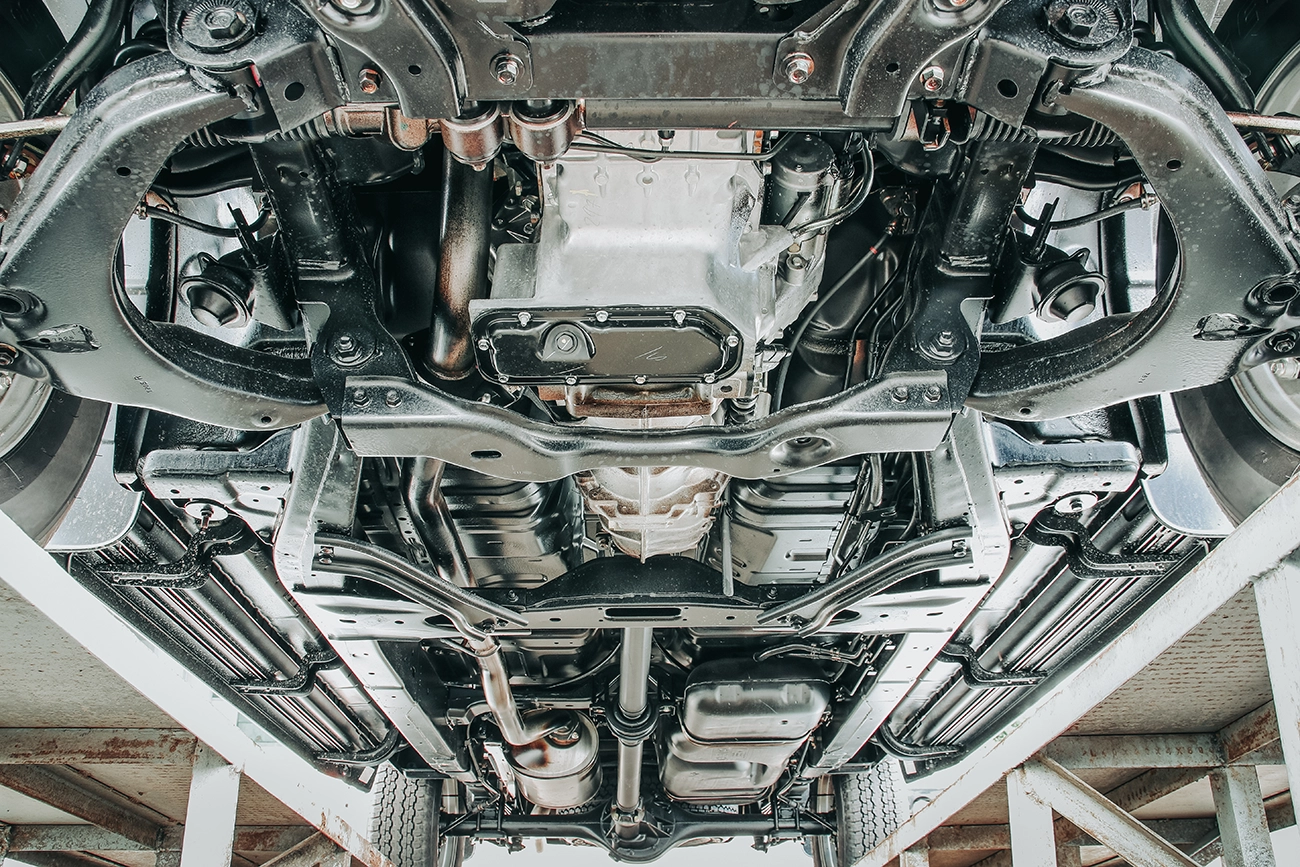

Undercarriage

An undercarriage inspection involves thoroughly checking your truck’s entire underbody, including the frame (chassis), exhaust system, brake lines, axels, and fuel tanks for damage, rust, or leaks. Since these components sit so close to the road, they’re constantly exposed to debris and impacts that can quietly degrade performance over time.

Annual inspections catch hidden problems like frame cracks, exhaust leaks, or corroded fuel lines before they turn into major failures or dangerous situations.

3. Listen To the Engine

Most truck owners use their vehicles every day, so it’s easy to get familiar with the way it sounds while operating. However, those rattles and clunks you’ve gotten used to could indicate serious engine problems.

Even if you think your engine is working fine, it’s a good idea to actively listen to how your truck sounds while it’s running. If you notice any of the following noises, your truck needs immediate professional attention:

- Grinding

- Popping

- Rumbling

- Squealing or chirping

- Sputtering

- Clicking

- Hissing or sizzling

If you’re ever unsure whether these sounds indicate a serious problem, the best course of action is to have a professional take a look just in case. When it comes to engine issues, it’s always better to be safe than sorry.

4. Inspect the Electrical System

It’s a good idea to have your truck’s electrical system inspected once a year or sooner, depending on how often you use it. This will include electrical components like lighting, battery health, and wiring:

- Lighting: inspecting turn signals, hazard lights, brake lights, tag lights, and any other lights your truck may have

- Battery: checked for corrosion, secure mounting, and charge

- Wiring: inspect for fraying, loose connections, exposed wires, and proper grounding for both the truck and any upgrades or accessories installed

Inspecting these components at least once a year helps keep your truck compliant with safety standards and prevents small issues from escalating into dangerous problems.

5. Diesel Pickup Truck Maintenance

If you drive a diesel pickup truck, your annual maintenance checklist should include a few additional items specific to diesel engines. These components help your truck run cleaner, more efficiently, and meet emissions standards.

Fuel Filter

Diesel fuel filters remove contaminants and water from fuel before it reaches the engine. Both gas and diesel systems need filters, but diesel engines often require more frequent filter replacement.

Check your truck owner’s manual to see how often to replace your diesel fuel filter.

Fuel Water Separator

Diesel fuel filters also have a fuel water separator that removes water from the fuel to prevent corrosion, poor combustion, and injector damage. If this element is clogged or damaged, it can’t filter properly. That’s why it’s important to inspect your truck’s water separator and clean or replace it according to your owner’s manual.

Diesel Exhaust Fluid (DEF)

Diesel exhaust fluid (DEF) is a solution that’s injected into the exhaust stream to reduce harmful nitrogen oxide emissions. Most modern diesel trucks have a separate DEF tank that needs regular refilling. DEF levels should be checked regularly and topped off as needed. Check your owner’s manual for specific recommendations.

Upgrade Your Pickup Truck at Campway’s Truck Accessory World

Annual maintenance is one of the best investments you can make in your truck’s longevity and performance. By keeping up with yearly inspections, you can catch problems early, save money on major fixes, and keep your truck safe and reliable for years to come.

But that’s not all you can do to help your truck work harder. At Campway’s, we sell a wide selection of truck accessories and upgrades designed to make your vehicle safer, more efficient, and equipped to your needs.

Visit any of our Northern California locations to browse our selection of truck accessories in-person and get professional on-site installation services.

References

- Heavy Vehicle Inspection Maintenance Report @JRS Innovation. (n.d.). Optimize Fleet Maintenance Costs with Benchmarking. HVI. https://heavyvehicleinspection.com/fleet-management/cost-roi/maintenance-cost-benchmarking